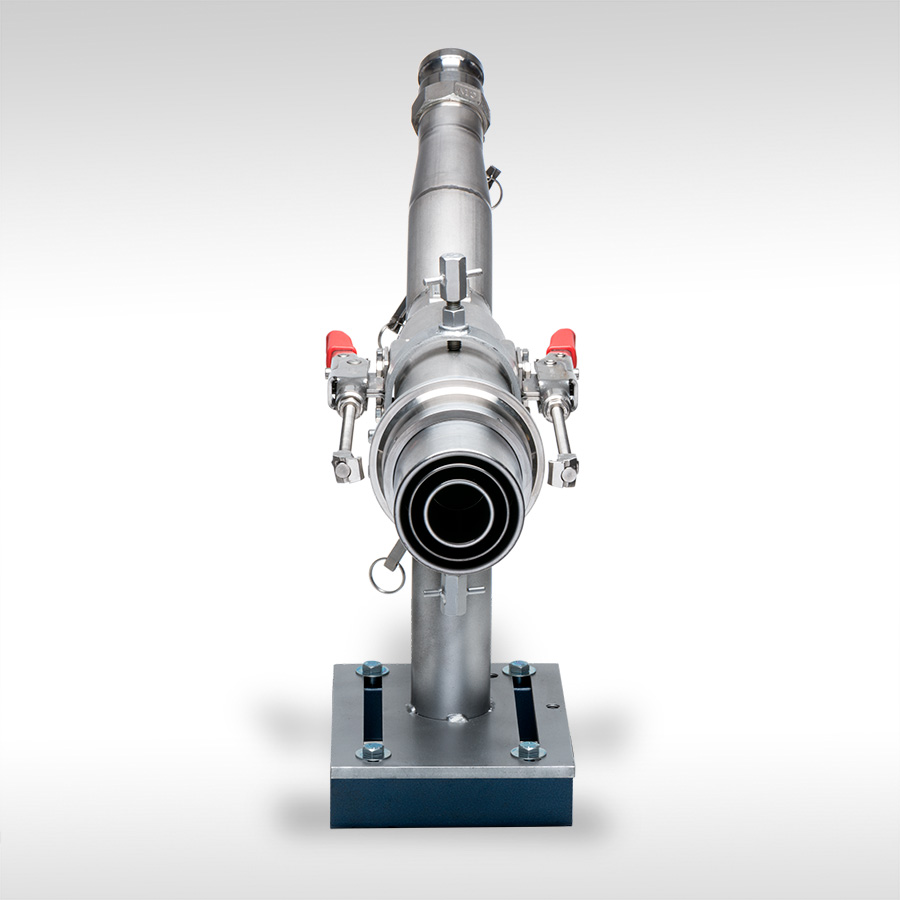

FT OXYGEN BURNER

Oxy Boosting / Full Oxy Gas Furnace

FT oxy/gas burner with three (3) unique gas inlets allows for great burner flexibility and optimal heat transfer from combustion to the glass melt, resulting in pull increase, very high furnace efficiency and extreme low emission when replacing conventional burners.

Technical Data

-

technical specs

fuel

natural gas, oxygencapacity

0.3 – 2 MW in 4 burner sizesgas flow rate

10 – 550 Nm3/hgas pressure at the burner

20 – 140 mbaroxygen pressure at the burner

15 – 120 mbar -

capabilities

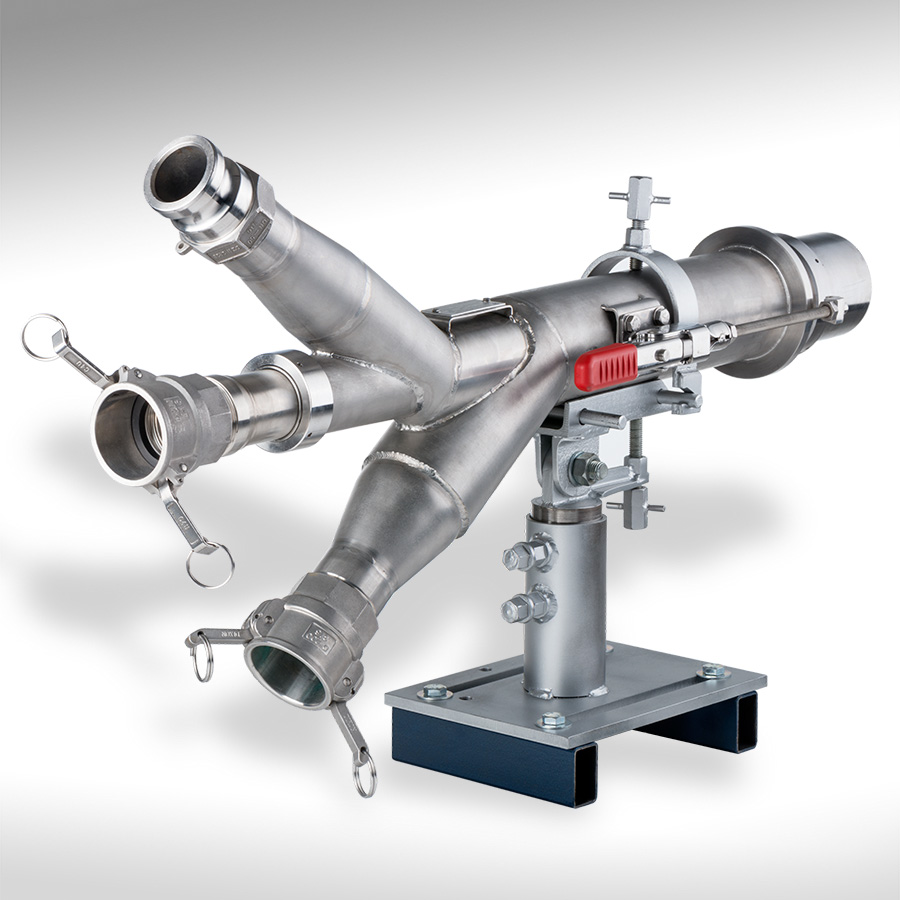

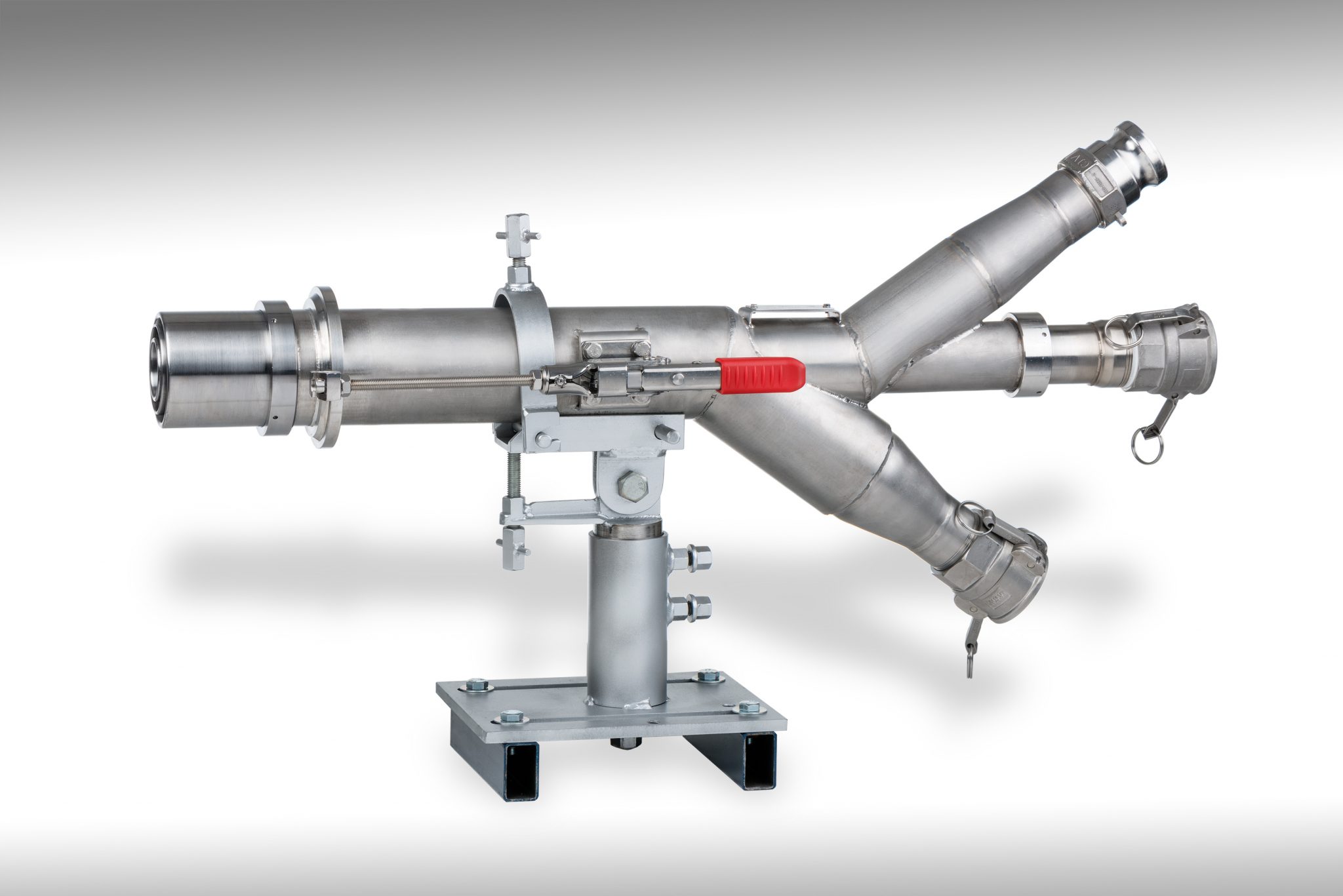

two oxygen inlets and one gas inlet to provide flexibility in velocity adjustment

low velocity and luminous flame

-

both oxygen streams are fully controlled with manual control valves

very low NOx level

Ask us to optimize your combustion process.

technological flexibility

- high flexibility and efficiency

- easy adjustment and control

- low NOx emissions

- adjustment repeatability

- possible remote control of flame shape and length

maintenance benefits

- higher pull-rate/m2 (smaller furnace)

- energy savings

- glass quality improvement

- no utilization of heat exchangers and their potential problems

- furnace flexibility improvement

- better forming conditions

scope of supply

- oxygen burners with the required capacity

- fully adjustable burner brackets

- burner blocks and socket plates

- all flexible hoses as required

- gas and oxygen spools, including all controls for directing the oxygen flow into the two oxygen inlets

options

- optimization of melting process using CFD simulation

- commissioning and optimization

- training of customer’s staff

- control panels & safety trains delivery of oxygen/gas skid

Further Information

-

Need to know more?

Please contact us

to receive more information,

our latest presentation,

or a quotation to purchase. -

-