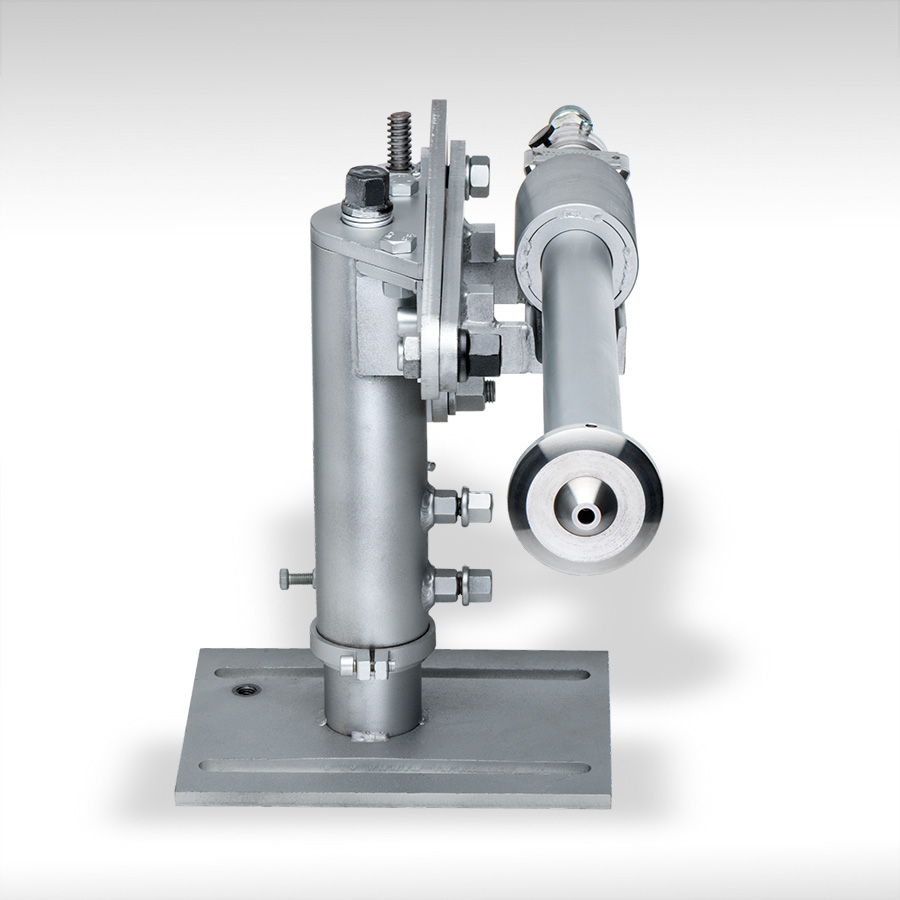

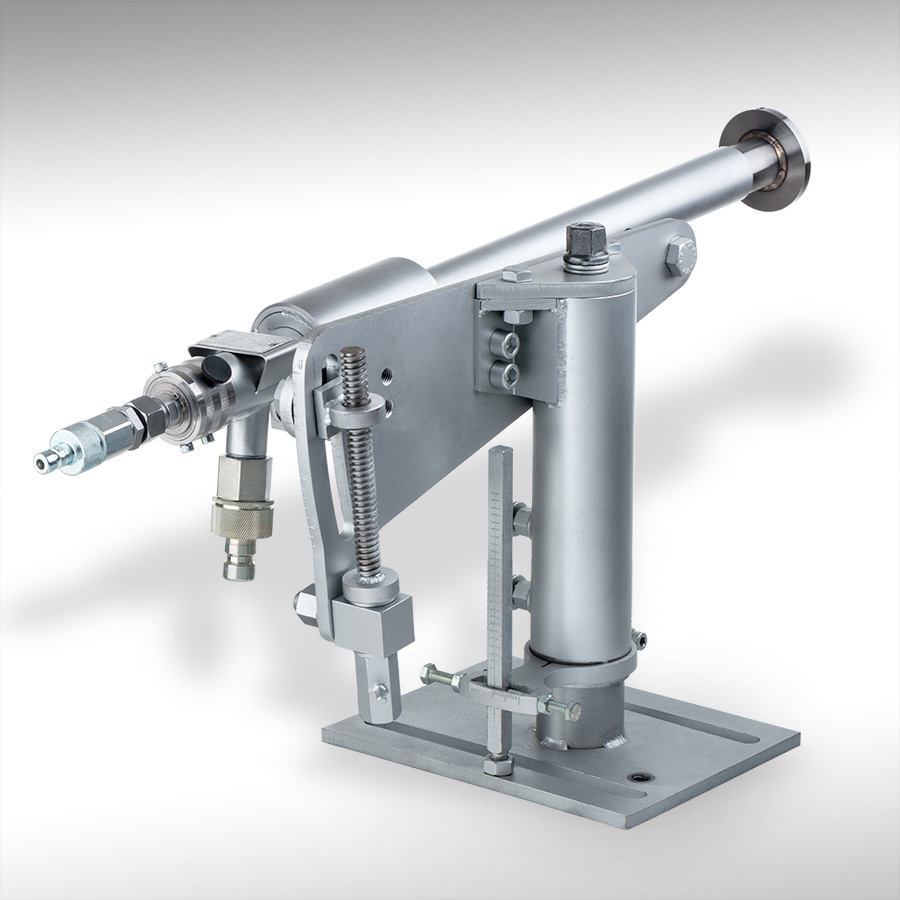

FT BACKUP HEAVY OIL INJECTOR

Underport Burner

FT heavy oil injector has a unique atomizing solution that results in optimal heat transfer from combustion to the glass melt, one of the highest furnace efficiencies, and extremely low emission when replacing conventional burners.

Technical Data

-

technical specs

fuel

heavy oilenergy output

0.26 – 5 MW in 4 injector sizesinitial pressure

6 – 10 baroperation pressure

1 – 4 bar + pressure atomized airpreheating

90 – 130 °Chybrid operation

natural gas 13 – 50% calorictempering operation

all types of oil fuel possibleatomizing

air or natural gas 10 – 80 Nm3/h

(0.5 – 3 bar)cooling air

8 – 25 Nm3/h

(0.5 – 1 bar) -

capabilities

novel configuration of inside atomizer allows for optimal free jet flow

optimized oil drop size distribution and minimized of inside fuel deposition

-

mushroom head fitting to gas injector shape

possible upgrade to dual firing

technological flexibility

- three (3) different operation modes of atomizing: inside atomizing (most reliable and low in maintenance), outside atomizing, double (combination) atomizing

- adjustable double atomizing

- primary flame cone angle: 15 – 40°, depending on atomizing operation mode

- modular design of burner body and media supplying pipes adapts easily to constructional limits of furnace design

maintenance benefit

- atomizing gas parts remain free of oil

- clean environment around injector’s working areas

- applicable for low-quality fuels

- long-working cycles of the injector without maintenance

- long survival time when lacking cooling air

- atomizer is tolerant when missing oil preheating

scope of supply

- heavy oil injectors with the required capacity

- fully adjustable injector brackets

- stainless steel flexible hoses

options

- optimization of melting process using CFD simulation

- rental and maintenance contract

- port design optimization

- regular service during and after warranty period

- control panels & safety trains delivery

Further Information

-

Need to know more?

Please contact us

to receive more information,

our latest presentation,

or a quotation to purchase. -

-